Circular Economy

"The circular economy is by no means the same as recycling"

Circular economy = recycling waste? Not only! Dr.-Ing. Stephan Kabasci and Dr.-Ing. Jochen Nühlen make it clear in an interview that there is much more to circular economy than recycling. The scientists also talk about the challenges on the road to the circular economy and explain how Fraunhofer UMSICHT can help overcome these hurdles – whether by developing technologies and materials or providing advice on the circular transformation.

What do you think characterizes a circular economy?

Stephan Kabasci: First of all, you have to be clear about what our current economic approach looks like. It is largely linear: Most products are designed and developed without thinking about the phase after the (first) use. Neither business models nor products are usually designed with this in mind – how to best preserve the value of the raw materials and materials used to manufacture the product or how these raw materials and materials can be used again for new products.

Jochen Nühlen: The circular economy, on the other hand, takes a different, circular approach: Products and processes are thought of in holistic utilization – with the aim of satisfying people's needs just as comprehensively as in the linear economy, but with less absolute use of resources and energy. Ideally, this goes hand in hand with the use of renewable sources for raw materials and energy and the reduction of emissions. In production, for example, waste and scrap are minimized and renewable energies are used or processes are set up that do not aim to produce new machines but to refurbish machines that are already in use. This requires a rethink in terms of design, process engineering and the resources used, as well as the associated business models. Looking at your own company is often not enough.

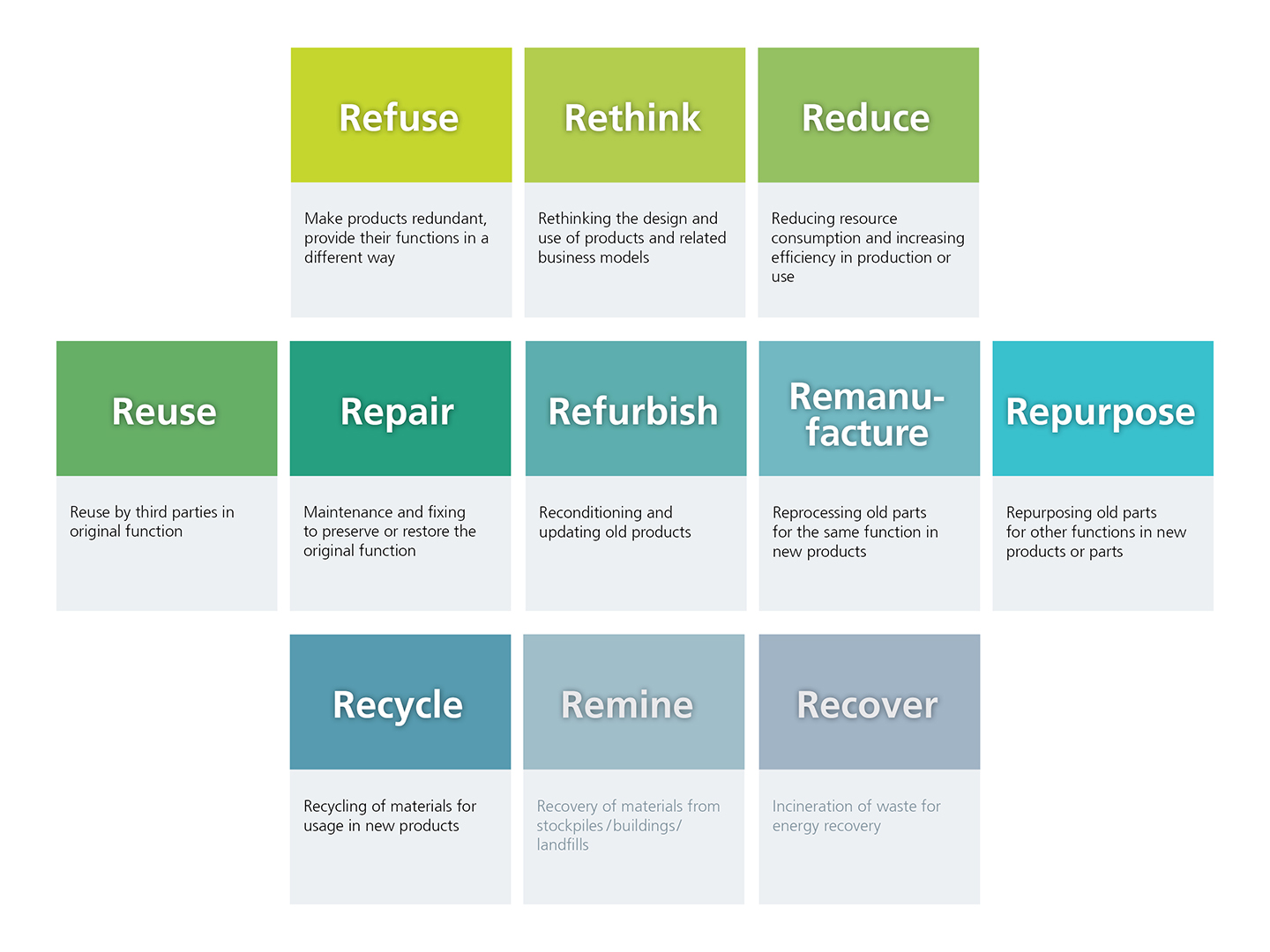

Stephan Kabasci: The R strategies, which specify the various building blocks and possibilities on the way to a circular economy, are now regarded as a good guide. They look at a product or raw material over its entire life cycle and address various measures that could enable a circular economy. The first R strategies Refuse, Rethink and Reduce have a particularly strong influence on circularity and resource consumption in the design of products and business models.

How far is Germany on the road to the circular economy?

Stephan Kabasci: This can be seen, for example, in the "Circular Material Use Rate" indicator from eurostat. This describes what proportion of the raw materials used in a national economy consists of recycled waste materials. With a value of 13% for 2022, Germany is in the upper midfield of the EU, which has a value of 11.5%. This looks good at first glance, but is a long way from the top values: Netherlands = 27.5 percent, Belgium = 22.3 percent and France = 19.3 percent. However, this indicator only looks at one aspect of how circularly companies and society think and act. After all, recycling is only one aspect of the circular economy.

Jochen Nühlen: That's right! Germany has long had the reputation of being the "recycling world champion" and our Circular Economy Act for the conservation of natural resources is also highly regarded around the world. But in my view, we have lost this lead and focused on an R strategy for too long. It is very important for a circular economy to look at the end of a product's life and offer technological solutions there. In my view, this strength that we have in Germany in this area must be understood as a basis and expanded step by step in sensible areas to include further R-strategies. There is great potential in using this very good recycling infrastructure and our innovative strength in this sector as a foundation for a circular economy. We should therefore simultaneously promote recycling technologies, but also consistently flank them with other R-strategies. My assessment is therefore that Germany has only just begun to move towards a circular economy.

Which sectors are doing best so far?

Stephan Kabasci: There is no general answer to this question and you have to take a closer look at the points in the value added chain where circular solutions and structures are already established and accepted by customers. In the food trade, for example, there are very effective reusable systems for transporting fruit and vegetables. Compared to disposable cardboard boxes, they are significantly more environmental friendly and also more economical, as we have shown in a study. In the mechanical engineering sector, some companies are actively working on their business models and structures in order to implement remanufacturing solutions or leasing models, for example. The chemical and construction industries have also been thinking a lot about closed loops in recent years.

What are the biggest challenges?

Stephan Kabasci: The circular economy has many facets, and the challenges and levers are correspondingly diverse. In addition, every company has different starting points and market situations, so generalizations are not helpful. In my opinion, however, the biggest misunderstanding is that many people in Germany essentially understand the circular economy to mean the recycling of waste and therefore decide too early that the topic has no relevance for them and their company. Recycling is only one component, there is much more:

- avoiding the manufacture of products by offering services

- using products together (sharing economy)

- reducing the use of materials and energy in production

- the replacement of fossil non-renewable resources with recyclates or sustainable biogenic raw materials

- the durable and modular design of products that are easy to repair

- the design of reusable systems in the packaging sector

- the establishment of further product- or material-specific recycling systems whose products, high-quality recyclates, offer genuine alternatives to virgin materials in production

Jochen Nühlen: Regardless of where a company conducts its business on the market, there are always points of contact and areas of development for a circular economy. It is always important to look closely with the company to see which of the R strategies is the most promising.

One of the major challenges we face in many discussions with industries on the path to the circular economy is the global flow of goods and resources. Regardless of the other advantages and disadvantages of globalized material flows, the value added chains are sometimes so branched that a company alone often cannot decide to set itself, its products and its business model up in a circular way. In addition to technological prerequisites, a lot of communication, rethinking and adjustments along the entire value added chain are necessary. The circular economy is a team game: It requires the will and motivation of all those involved, as well as the political framework! If one component of the value added chain is not convinced of the added value, is not properly involved and picked up, or technological solutions are still in their infancy, it is often difficult to actually implement them. It is clear that this transformation does not always happen overnight, but there is still enormous potential. In our discussions and projects, we often experience real "aha" moments with regard to the contribution possibilities. As in any transformation process, regulatory hurdles must also be overcome: Laws and regulations need to be further developed in order to comprehensively support and promote this circular economy and create the framework conditions.

Circular Economy is a research focus of Fraunhofer UMSICHT. What is the current focus?

Stephan Kabasci: Our scientists conduct research into process engineering for the circular economy, develop circular materials and advise companies and even countries on the circular transformation. A total of seven departments at our institute are involved in this – five of them at the Oberhausen/Willich site and two in Sulzbach-Rosenberg. The focus is on the circular plastics economy and the recycling of water, plant nutrients and valuable components from wastewater.

Jochen Nühlen: To set a few highlights and illustrate the scope of our research and development work: For example, we recently presented the first comprehensive nationwide waste strategy for a country in the Gulf region and created a real milestone with Kuwait, which will shape the next 20 years of the circular economy strategy there. However, we are also involved in a number of specific material development projects. In the MoNova project, for example, we have developed a polyolefin-based mono-material film together with three other Fraunhofer Institutes. By limiting the films to a single type of polymer, they can be recycled and turned back into raw materials for new packaging. In this way, intelligent material design – tailored to the application and its requirements – can create a material cycle. Incidentally, at Fraunhofer UMSICHT we also coordinate the Cluster of Excellence Circular Plastics Economy CCPE – a collaboration of six Fraunhofer institutes with the goal of transforming to a circular plastics economy.

As Stephan has already indicated, as a process engineering institute we also enable cycles with specific technologies. We operate large-scale thermochemical conversion processes as well as the associated treatment and purification processes for the resulting products. In this way, we are driving forward the production of defossilized chemicals and basic materials for new plastics from biomass, waste and residues and enabling circularity where previously no recycling was possible. Here at the institute, we also work closely with colleagues who pay particular attention to the recycling and use of carbon.

Our teams are also working on nutrients or valuable elements from aqueous media. In the Suskult project, for example, we are working on the recycling of important nutrients such as phosphorus and nitrogen, water and energy by technologically realizing a symbiosis between agriculture and sewage treatment plants. The circular economy has many facets, which are of course also reflected in our projects.

What can cooperation with Fraunhofer UMSICHT in the field of circular economy look like?

Jochen Nühlen: This can take place either in direct cooperation or in a larger collaborative project in which several partners along the value added chain work together on a circular solution. For example, a company may want to launch a circular material or product innovation on the market, have an internal production process evaluated and improved or respond to anticipated market demand as quickly as possible. Together, we clarify the framework conditions for how we can successfully help companies with our expertise and infrastructure in the field of circular economy. It doesn't matter how big the company is. We support small companies just as professionally with research and development services as clients from SMEs or DAX companies.

Stephan Kabasci: In terms of content, the focus can be on a technological innovation or further development as well as the scientific evaluation or development of a defined R-strategy for the circularity of a product or material. Together with the companies, we research funding opportunities for these innovation projects.

As Jochen already mentioned, a sustainable energy supply is also an enabler of a circular economy. At the institute, we benefit greatly from the fact that we also have a major focus on research into energy systems for climate-neutral commercial and industrial sites as well as the production, storage and use of green hydrogen. This often opens up new ways of thinking for our customers and offers companies the holistic utilization they need.

Last modified:

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT