The electrification of chemical processes plays a crucial role in achieving climate neutrality: The necessary reaction temperatures are achieved and maintained using microwave, inductive or direct resistance heating. In other words, electricity from renewable sources replaces fossil fuels and enables CO2 emissions to be reduced.

Direct resistance heating of chemical reactors

Solutions and services from Fraunhofer UMSICHT: From catalyst development to process demonstration

Catalysts play a crucial role in the direct resistance heating of chemical reactors: they enable reactions to take place at lower temperatures and at higher speeds. As a result, energy consumption is reduced, and process efficiency is increased. And this is where Fraunhofer UMSICHT comes into play: We develop new catalytically active materials for different processes or look at existing materials and investigate how they react under process-relevant conditions. Looking at their use in directly resistance-heated reactors, the catalysts are functionalized, i.e. sufficient electrical conductivity is ensured. This can be achieved, for example, by coating an electrically conductive carrier body or by extruding electrically conductive solid catalysts.

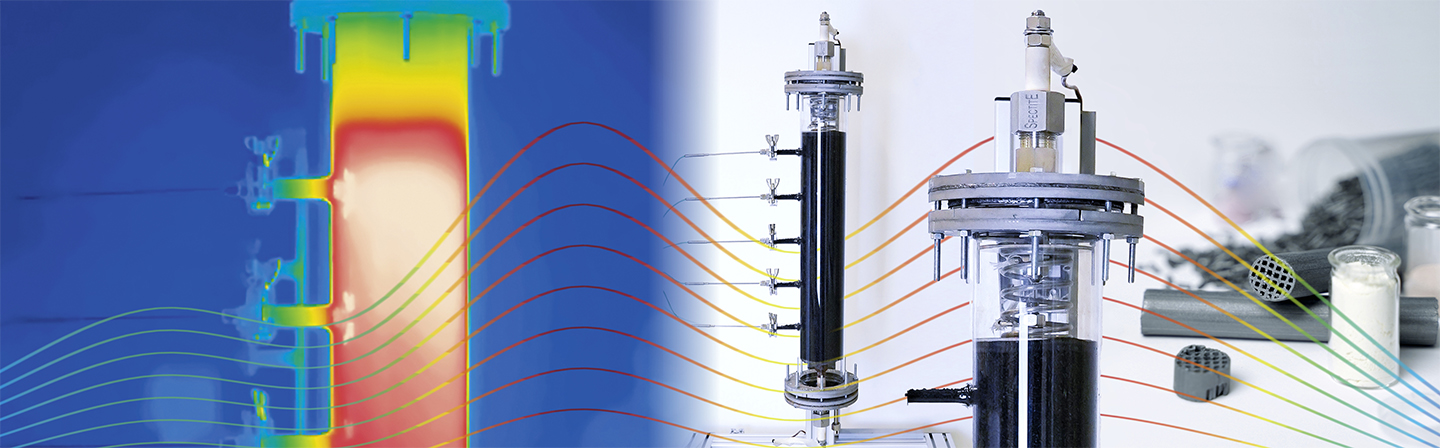

Testing takes place in specially developed reactors. The focus is on issues such as the arrangement of the electrodes and their contact with the conductive material. To this end, the reactor design must be closely coordinated with the material development. Subdivision into different temperature zones enables targeted reaction control. Processes heated in this way can be operated more flexibly and dynamically and are easier to set up.

By carrying out a simulation in parallel, we can perform a reactor design by reverse modeling and compare different operating modes. This enables us to make statements on material and energy balances as well as economic key figures (CAPEX and OPEX).

Unique selling point: From catalyst development to process demonstration

We offer you the material, reactor and process development from a single source. This enables us to support you in the climate-friendly, efficient and cost-effective design of your chemical processes. Our services include

- Development of new and optimization of existing electrically conductive catalysts

- Specialized reactor designs

- Simulation and reverse modeling

How the collaboration with us works

We see ourselves as a link between academic research and industry in order to transfer innovative and promising catalytic materials and processes into technical applications. Cooperation is possible both within the framework of publicly funded research projects and in the form of direct commissioning.

Further information

Catalysts for industrial use

Ammonia as a hydrogen storage medium

Comparison of the Prediction of the Temperature Profile in an Ohmic Reactor on Different Modeling Scales

Catalytic Conversion of Ethanol with Conventional and Ohmic Heating in Comparison

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT