Green Hydrogen

Carbon-based bipolar plates have the potential to replace titanium bipolar plates in the electrolysis stack

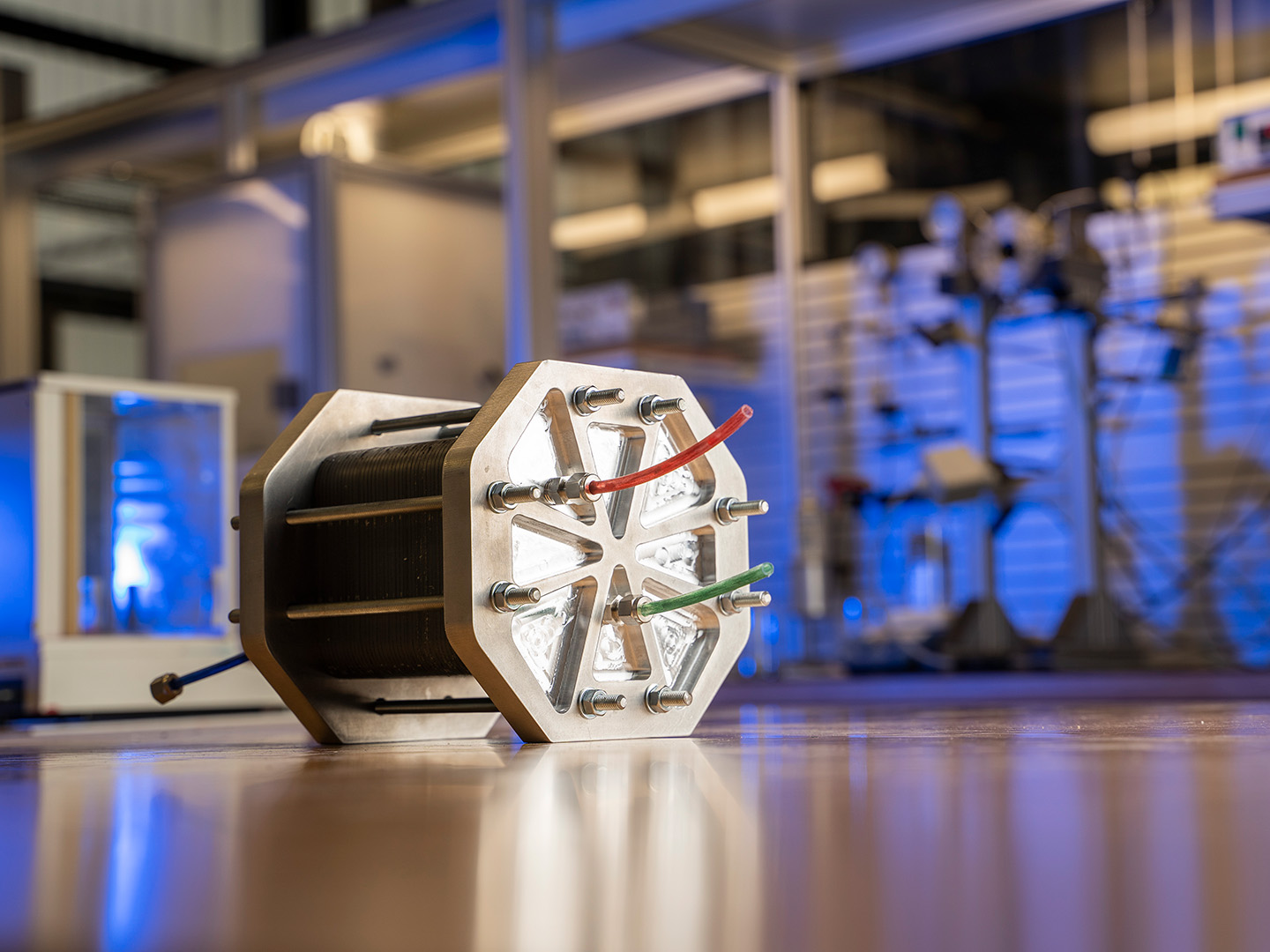

Proton exchange membrane electrolysis is considered the most promising way to produce green hydrogen. However, it is still not very economical at the moment. One reason: One of its key components – the bipolar plate – is usually made of titanium. The metal impresses with its corrosion resistance during electrolysis, but is more expensive than other metals due to its complex extraction and processing. Researchers at the Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT and Ruhr University Bochum have discovered that carbon-based bipolar plates can be a more cost-efficient and scalable alternative.

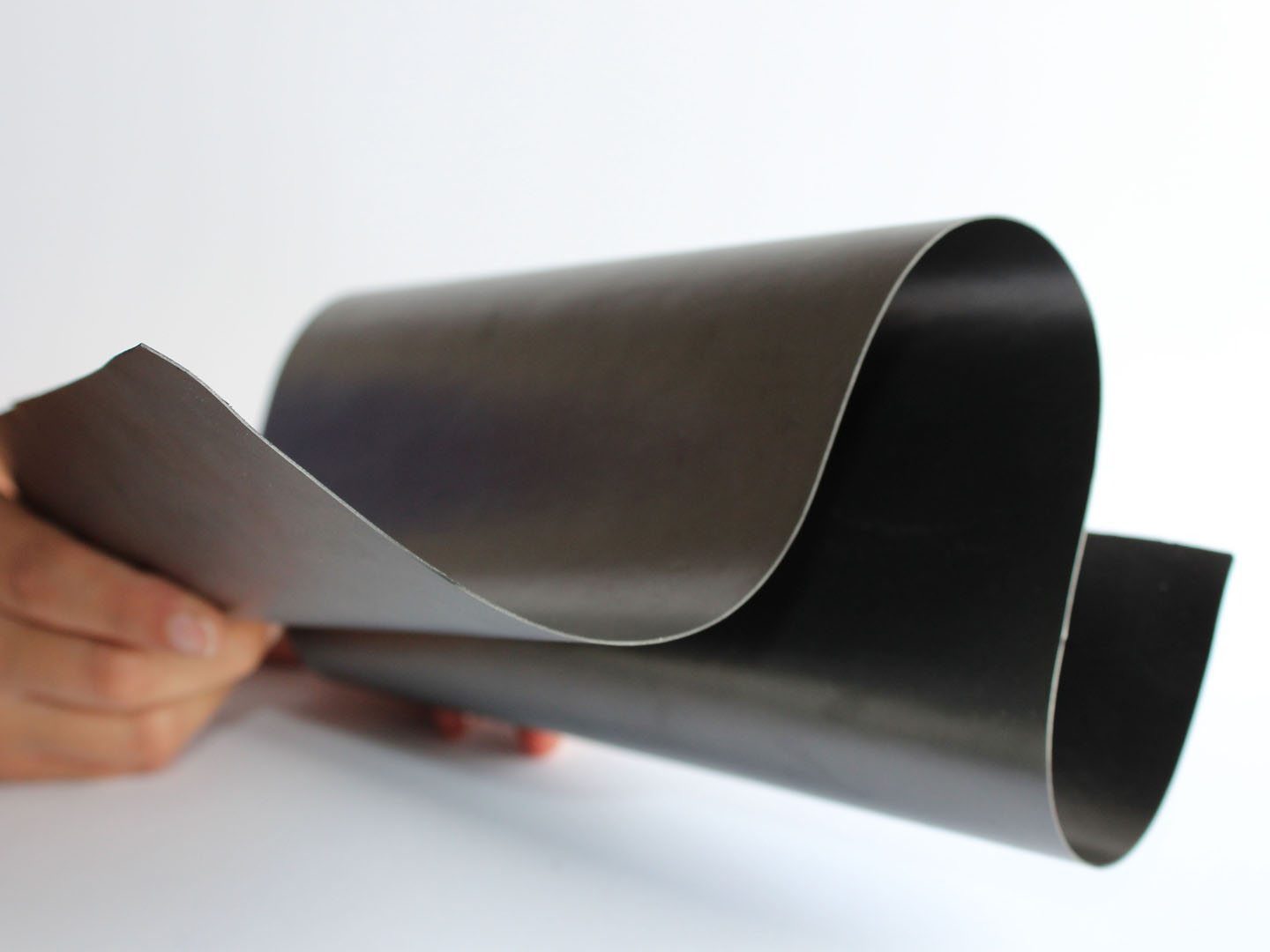

The focus of their investigations was a new carbon-based bipolar plate – developed and patented by Fraunhofer UMSICHT. It consists of a thermoplastic polymer-bonded carbon matrix with conductive additives such as carbon black and is produced in a powder-to-roll process. The material and production process enable the continuous manufacturing of a bipolar plate that is both easy to process and weld and is already being used commercially in the field of redox flow batteries.

The researchers have subjected this bipolar plate and a bipolar plate made of titanium to comprehensive ex-situ and in-situ tests. In the ex-situ tests, they carried out electrochemical corrosion studies, then analyzed the corrosion in scanning electron microscope images and measured the weight loss of the carbon-based bipolar plate to assess its suitability for real applications and the choice of parameters. During the in-situ tests, the bipolar plates were subjected to accelerated ageing tests with alternating current densities between 1 and 3 A cm-2 for over 500 hours.

The scientists have published their results under the title “Bipolar Plates in PEM Water Electrolysis: Bust or Must?” in the journal “Advanced Energy Materials”. In essence, they have discovered that the carbon-based bipolar plate has an ageing rate in the low µV h-1 range and thus shows promising performance. This means that it can certainly compete with titanium bipolar plates and represents a much more cost-effective alternative. Another advantage: due to its material properties such as weldability, it enables completely new designs for PEM electrolysers. The potential to replace titanium bipolar plates in the PEM electrolysis stack and make electrolysis scalable at the same time is therefore definitely there. The task now is to further investigate and, if necessary, optimize the new material in order to further reduce the costs of electrolysis and thus make the production of green hydrogen more economical.

Original publication

Leonard Messing, Kevinjeorjios Pellumbi, Lucas Hoof, Niklas Imming, Steffen Wilbers, Lukas Kopietz, Michael Joemann, Anna Grevé, Kai junge Puring, Ulf-Peter Apfel: Carbon Bipolar Plates in PEM Water Electrolysis: Bust or Must?, in: Advanced Energy Materials. https://s.fhg.de/u87

Last modified:

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT