Cleantan®

European Innovation Award EARTO 2017 for leather tanning process

Fraunhofer UMSICHT developed a completely innovative leather tanning process that reduces emissions and production costs. The process can contribute to retain and strengthen leather-manufacturing companies in Germany and Europe. For this process Dr. Manfred Renner was awarded one of two innovation awards of the European Association for Research and Technology Organisations EARTO. With this award the international non-profit association honors products and services with a high social and economical benefit for the EU.

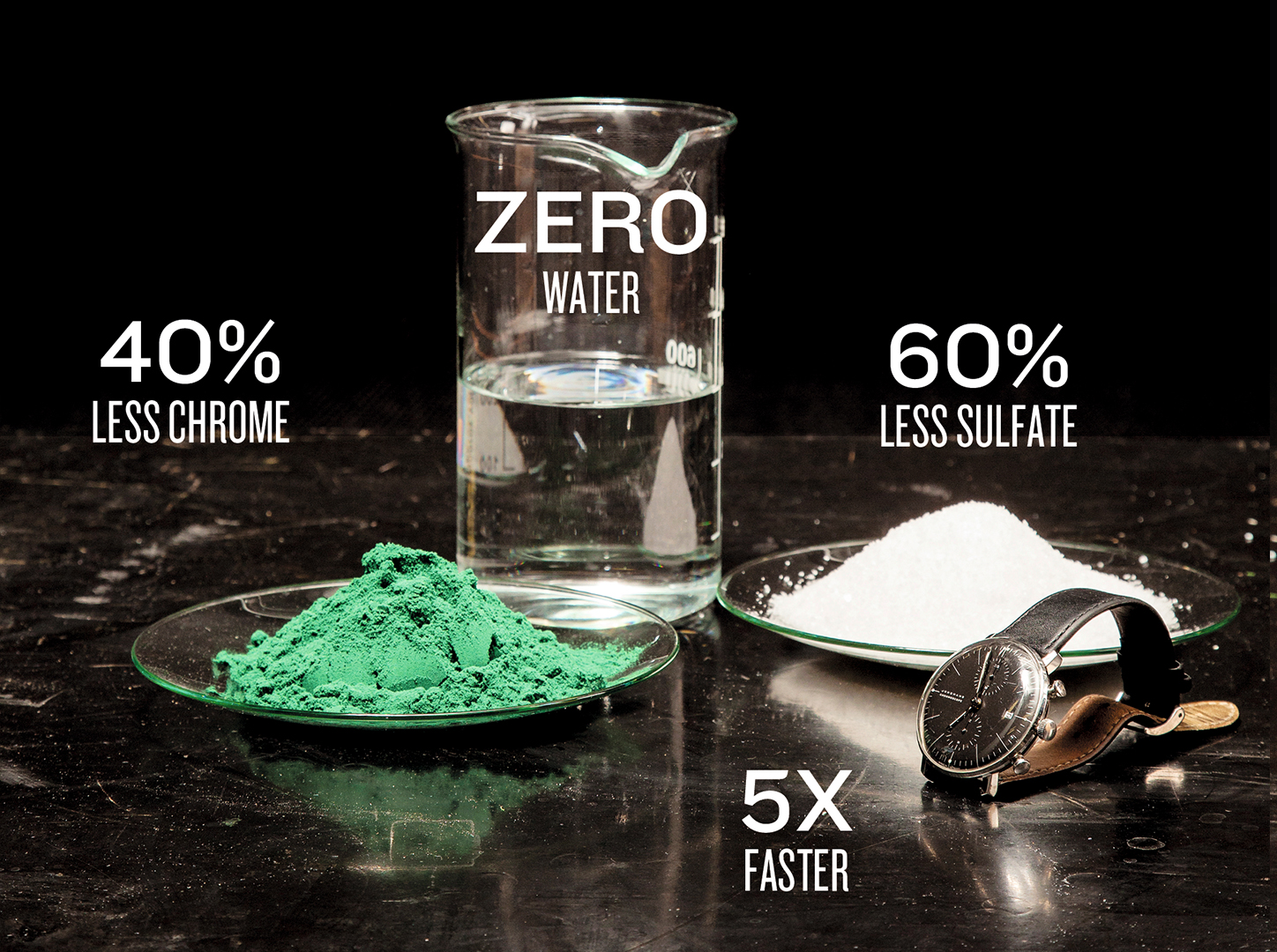

Leather is a popular and high-quality material. However, the tanning process, is anything but efficient. In leather tanning, for 90 % of all tanned leather worldwide chromium salt serves as a tanning agent. Up to 40 percent of these salts end up in wastewater, and a recycling is subject to extensive process engineering and is cost-intensive. With the new CLEANTAN® process, Fraunhofer UMSICHT reduces the chromium-contaminated wastewater nearly completely. Other advantages of tanning with the CLEANTAN® process: Reduction up to 60 % of the sulfate load within the wastewater, reduced processing time by a factor of five and a significant cost reduction by a lower utilization of chromium salt as a tanning agent up to 40 %. A return-on-investment of the new plant technology can be achieved within two years. The potential of the tanning process is very high on a national, European and on an international level.

Customer benefits: Competitive advantage and improved image

The leather manufacturing industry is being faced with increasing pressure to reduce the emissions in the tanning process. With the CLEANTAN® method, the researchers of Fraunhofer UMSICHT offer companies an effective and economic solution. Since the companies are saving 40 percent of the costs for the tanning agent and almost the complete costs for the disposal of the chromium-contaminated wastewater, the system amortizes within 1.5 to 2.5 years. From that point in time on, the method is significantly more cost-effective than the current one – and as such provides for an enormous competitive advantage. The improved image due to the environmentally friendly and sustainable process should also be very huge. As such, CLEANTAN® can become an important component for retaining and strengthening the leather-producing companies in Germany and Europe. Since the prerequisites severely differ depending on company size, site, and product, the researchers of Fraunhofer UMSICHT develop the return-on-investment calculation confidentially with the respective client.

Awarded in the category »Impact Expected«

Theses facts convinced the jury of six consisting of members from science, industry and politics. Thus, the new tanning process that is environmentally-friendly, sustainable and cost-efficient was given the EARTO Innovation Award 2017 in the category »Impact Exptected«. The category »Impact Exptected« addresses innovations which are not yet available but offer a great potential social or economical impact.

Last modified:

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT